Gravity conveyor components

Gravity conveyor frames, rollers and supports

A gravity conveyor is ideally suited for handling operations which cannot justify the expense of powered equipment.

They provide an efficient and economical way to move manufactured goods from one process to the next, increasing your productivity and reducing labour costs.

Gravity conveyors are also very easy to set up, dismantle or relocate. They work on one of the following principles:

-

One stand is lower than the other, and gravity moves the load.

-

The frame is level, and the load is pushed along.

Gravity conveyor frames, rollers and supports are available in a variety of standard sizes and configurations.

How to choose the right conveyor for your application

1. Item size

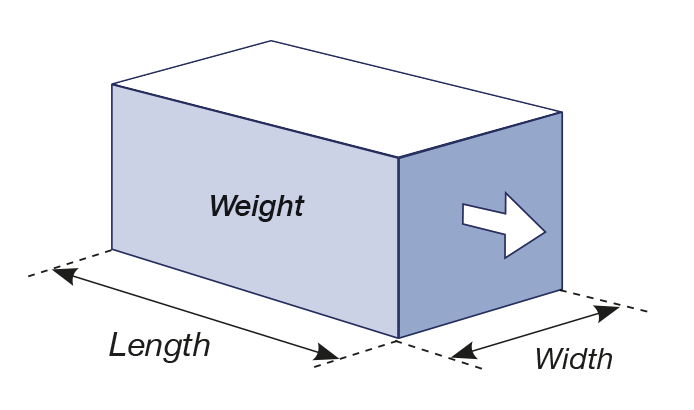

Measure the dimensions (length x width) and weight of the largest and smallest items to be carried on the conveyor, to ensure there are three rollers under the item at all times for stability.

2. Frame width and length

Choose the frame width closest to the width of the items being conveyed. The rollers sit 10 mm above the roller frame. Overhang should be minimal.

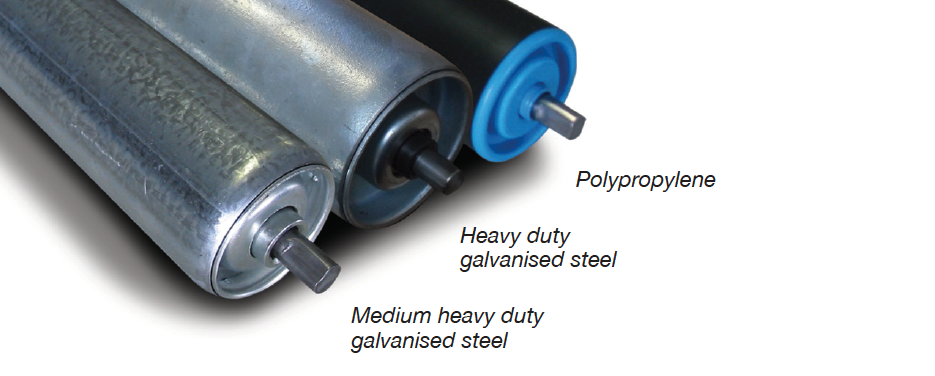

3. Rollers

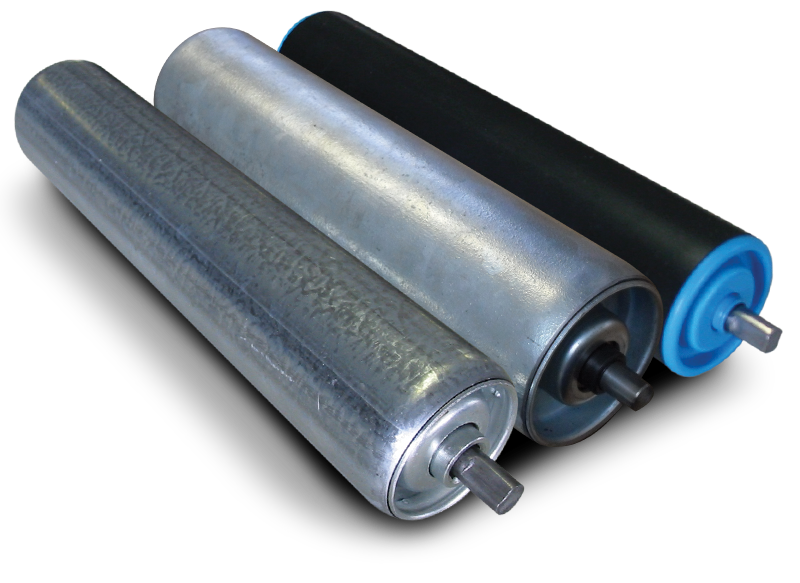

The product being conveyed determines which rollers are best for your application.

Medium heavy duty steel rollers are generally used for the conveying of heavy boxes and lengths of steel, whereas polypropylene rollers are more suitable for lightweight boxes and items you don't want marked, such as aluminium.

4. Supports

The conveyor supports are RHS steel construction, height adjustable from 600 to 900 mm (1000 mm to top of roller when fully extended) and have a Hammertone Regal Blue painted finish.

Supports can be bolted to the floor and to the conveyor system for added stability. Support can also be ordered with capped ends with a single hole to allow castors to be fitted.

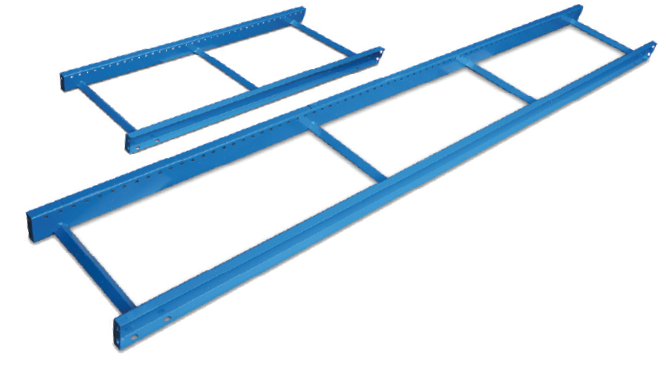

Frames

Australian manufactured conveyor frames

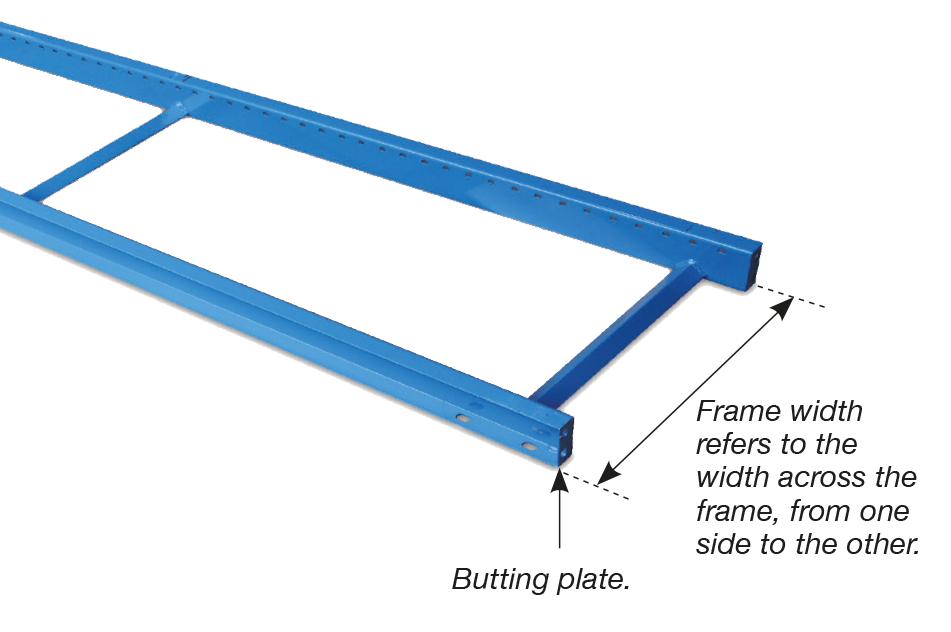

Frames are all laser cut (matched) C-channels with fully-welded cross braces. Butting plates on ends are integral and folded as part of the laser process.

Three standard frame widths:

-

305, 460 and 610 mm (measurement is over the frame).

Two standard frame lengths:

-

1500 and 3000 mm.

Medium heavy duty frames can only be supplied with MHDGAL or POLY rollers with 3/8" round shafts. Heavy duty frames can only be supplied with HD rollers with 12 mm round shafts

Features

-

Frames have fully welded cross braces (frames are not bolted together).

-

Frames have laser cut holes at 79 mm and 115 mm pitch as standard, with laser cut holes in the bottom of the channels to allow supports to be mounted in three positions (each end and at mid-span on the 3 m frames) and two positions (each end on a 1.5 m frame).

-

Each end of the folded butting plates are pre-drilled to allow splicing together.

-

The tops of the frames have holes pre-drilled to allow for the mounting of guide rails if required.

-

Painted Hammertone Regal Blue painted finish.

Medium heavy duty (MHD)—1500 mm long x 2.5 mm thick gravity conveyor frame.

Overall frame |

Inside frame |

Order |

|

|---|---|---|---|

305 |

242 |

CF15X305MHD |

|

460 |

394 |

CF15X460MHD |

|

610 |

546 |

CF15X610MHD |

Medium heavy duty (MHD)—3000 mm long x 2.5 mm thick gravity conveyor frame.

Overall frame |

Inside frame |

Order |

|

|---|---|---|---|

305 |

242 |

CF3X305MHD |

|

460 |

394 |

CF3X460MHD |

|

610 |

546 |

CF3X610MHD |

Heavy duty (HD)—1500 mm long x 2.5 mm thick gravity conveyor frame.

Overall frame |

Inside frame |

Order |

|

|---|---|---|---|

305 |

242 |

CF15X305HD |

|

460 |

394 |

CF15X460HD |

|

610 |

546 |

CF15X610HD |

Heavy duty (HD)—3000 mm long x 2.5 mm thick gravity conveyor frame.

Overall frame |

Inside frame |

Order |

|

|---|---|---|---|

305 |

242 |

CF3X305HD |

|

460 |

394 |

CF3X460HD |

|

610 |

546 |

CF3X610HD |

Supports

RHS supports are bolted to the frame through a crescent plate which allows for angular alignment. They have a strong, rigid construction, making them suitable for more permanent conveyors.

Straight frames require only one support per join (ie, three supports for two frames). However, if the frames are to be moved, it is usually more convenient to have a support at each end (ie, four supports for two frames).

Features

-

RHS construction.

-

Height is adjustable from 600 to 900 mm (1000 mm to top of roller when fully extended).

-

Hammertone Regal Blue painted finish.

-

Supports can be bolted to the floor and to the conveyor system for added stability.

-

Supports can be ordered with capped ends and a single hole to allow castors to be fitted.

Standard sizes

Suits conveyor |

Order |

|

|---|---|---|

305 |

CS305 |

|

460 |

CS460 |

|

610 |

CS610 |

Rollers

Rollers can be supplied in:

-

1.6 mm wall medium heavy duty galvanized steel tube.

-

2.8 mm wall polypropylene tube.

-

2 mm wall heavy duty galvanized steel tube.

Medium heavy duty (MHDGAL)

-

50 mm diameter x 1.6 mm wall galvanized steel tube.

-

3/8" diameter spring loaded mild steel, round shaft with 'D' one end.

-

Unground steel bearings.

-

15 mm shaft protrusion each end of bearing.

Overall frame |

Inside frame |

Over bearing |

Order |

|

|---|---|---|---|---|

305 |

242 |

240 |

CR240MHDGAL |

|

460 |

394 |

392 |

CR392MHDGAL |

|

610 |

546 |

544 |

CR544MHDGAL |

Heavy duty (HDGAL)

-

50 mm diameter x 2 mm wall galvanized steel tube.

-

12 mm diameter spring loaded mild steel, round shaft.

-

Precision bearings.

-

15 mm shaft protrusion each end of bearing.

Overall frame |

Inside frame |

Over bearing |

Order |

|

|---|---|---|---|---|

305 |

242 |

240 |

CR240HDGAL |

|

460 |

394 |

392 |

CR392HDGAL |

|

610 |

546 |

544 |

CR544HDGAL |

Polypropylene (POLY)

-

50 mm diameter x 2.8 mm wall polypropylene tube.

-

3/8" mm diameter spring loaded mild steel, round shaft with 'D' at one end.

-

Plastic caged bearings.

-

15 mm shaft protrusion each end of bearing.

Overall frame |

Inside frame |

Over bearing |

Order |

|

|---|---|---|---|---|

305 |

242 |

240 |

CR240POLY |

|

460 |

394 |

392 |

CR392POLY |

|

610 |

546 |

544 |

CR544POLY |

Custom-made gravity conveyor rollers

For information on custom-made gravity conveyor rollers, click on the link below.

Gravity conveyor packages available

We have various conveyor packages available to suit your application. Browse the options or contact us for more information.